Close

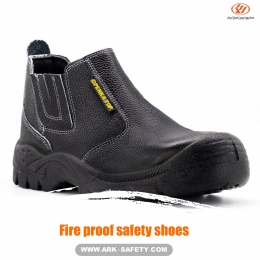

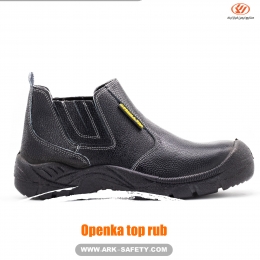

Openka top rub

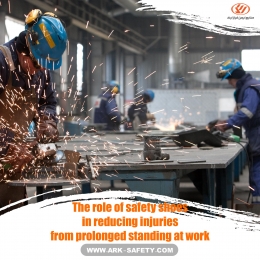

In blacksmithing, welding and turning workshops, you often come across to sparks and welding lava that cause burns to your feet, soles and even your shoelaces.

Choosing the right welding shoes is one of the ways to protect your feet, but unfortunately it is usually chosen unprofessionally and unprincipled, which both reduces the life of the product and increases consumer dissatisfaction with safety shoes.

Welding safety shoes have features that other safety shoes do not have.

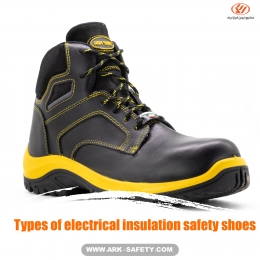

1 - Shoe material

Shoes made of synthetic leather burn immediately and destroyed by sparks, which reduces the useful life of safety shoes. Due to the fact that the safety shoes introduced are all cow leather, they are resistant to welding and turning projectiles.

2- Shoe upper

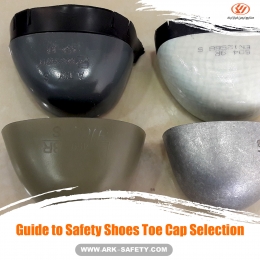

In welding safety shoes, it is very important that the sole of the shoe is closed. The welding shoe should completely cover the foot up to the ankle, and this cover should have a good resistance against penetration of objects and lava. Also in welding safety shoes, wearing and removing shoes should be done easily.

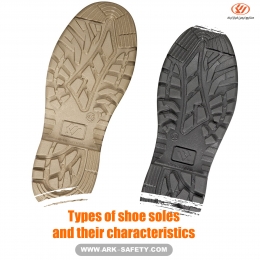

3- Shoe soles

The sole of welding shoes is better to be made of rubber. Rubber has good resistance to melting and penetration of welding projectiles and increases the life of the shoe. Due to the low resistance of PU to ambient heat, the use of PU outsole is not recommended.

In this regard, the special safety shoes for welding that we can introduce to you are the Openka Top-Rubber (rubber) safety shoes. Which completely covers the foot and is resistant to the penetration of foreign objects. The heat-resistant outsole is made of rubber and has a PU top on the front of the shoe sole.

Source: Ark Safety Company

Source: Ark Safety Company

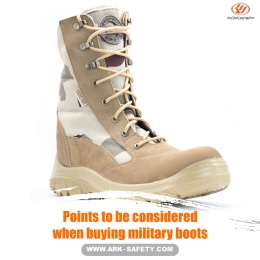

Military Shoe

Military Shoe

Safety Shoe

Safety Shoe

Work Wear

Work Wear

Office Shoe

Office Shoe

Hiking Shoe

Hiking Shoe