Close

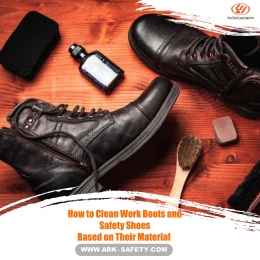

How to Clean Work Boots and Safety Shoes Based on Their Material

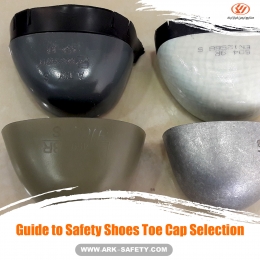

Work boots or safety shoes are an essential part of personal protective equipment used in the workplace to reduce physical hazards. Safety shoes are used to protect our feet while maintaining and cleaning them is essential for keeping feet healthy and safe. Cleaning and monitoring of safety shoes to avoid reducing their effectiveness in protecting the feet are very important. Here are the best ways to clean shoes based on the type of material used.

Leather

Leather is one of the most popular materials used in the exterior of safety shoes. The reasons for using leather in safety shoes are its high resistance to wear and tear, as well as the flexibility of movement that it shows during heavy work. Natural leather also absorbs moisture to keep the feet dry and comfortable during the day.

The first step in taking care of your leather shoes is to make sure your shoes are completely dry. Then it is necessary to use a shoe brush to remove dust, salt, and other sticky materials on its surface. The next step is to apply the appropriate wax or leather material and rub it on the shoe using a soft cloth. Keep doing this until the wax reaches the entire surface of the shoe and the stains disappear from the surface of the leather shoe. After that expose the shoe to the open air to dry. To keep the leather shiny, you can use waxes based on palmitoleic acid (like mink oil), which has similar properties to Vaseline. Finally, the use of the waterproof spray is recommended to protect safety shoes against snow and rain stains and help it withstand water penetration.

To remove grease stains and protein stains (such as blood or urea), use a cloth soaked in a solution of water, mild soap, and a very small amount of vinegar and smoothly wipe the area. It should be noted that in this case, to dry leather shoes, they should not be exposed to direct sunlight and heat.

Synthetic

Synthetic materials are also used in the production of safety footwear, and are composed of materials that have been manmade, rather than are natural. Synthetic materials can be treated to prevent staining, wrinkling, improve water-resistance and so forth, but how should you clean it?

We recommend removing stains and contaminants on the surface of the synthetic leather with a soft brush or cloth. Then use a mild soap solution and cold water to wash the safety shoes with synthetic leather. After cleaning, to make synthetic shoes dry, expose the safety shoes to the air, and the heat will have a positive effect on the synthetic leather construction.

Suede

Suede is a type of leather that has a non-glossy top layer with a special finish. Suede leather is usually softer than regular leather and has less strength and durability. Due to the lower resistance of suede maintenance of it is more sensitive.

To start cleaning and maintaining the suede, use a suede shoe brush to remove any dirt and salt. Then apply a dilute solution of sodium bicarbonate, also known as baking soda, to the remaining stains and the entire surface of the suede and allow it to absorb the sunscreen over a day. Then clean the safety shoe with a cloth and remove the baking soda from the surface of the shoe. Finally, use a special waterproof spray to make your suede safety shoes more resistant to the water and weather. Glossy sprays and oils such as paraffin cannot be used to maintain the beauty and appearance of suede.

Rubber

Rubber is another material commonly used in the manufacture of safety shoes. Rubber is an excellent insulator that makes the shoe electrically resistant and has shock-absorbing properties. Although the rubber has high durability, it is not breathable and it can restrict the movement of the shoe and cause discomfort. However, the rubber is water-resistant and allows people to work in humid environments to keep their feet dry during the day. It is relatively easy to clean safety shoes with a rubber material.

Use high pressure water to clean your rubber shoes and use baking soda solution to remove dirt. The pressure of the water cleans the mud and other materials, and baking soda removes the remaining stains on safety shoes made of rubber. Care should be taken to ensure that no water enters the shoe. Water penetration into the shoe can damage the inside of the shoe. After removing dust and stains on the plastic, use a stiff brush to separate any pebbles and sand from the sole of the shoe. Scratches on plastic shoes can be removed with olive oil. Finally, expose the shoes to the air to dry.

Final advice of Ark Safety Industry experts

Before buying any type of safety shoes, it is better to check the conditions of the work environment and the place of use. It is recommended not to use suede or nubuck leather for oily, wet, and muddy environments. In addition, because leather is a natural material with a protein base, the use of leather safety shoes in environments prone to the growth of enzymes and bacteria, which may damage the structure of the leather, should be considered deeply.

Given that most Ark safety shoes are made of leather if you want to clean your work shoes or safety shoes with water, be sure to consider the amount of water you use for cleaning. Repeated soaking of leather with water causes the leather shoes to dry and crack. If you have to expose your shoes or safety shoes to too much water, remove the insoles and fill them with the newspaper. During the hours when you are not using safety shoes, placing a newspaper inside the shoe will absorb the water and moisture faster. Of course, the use of leather shoes in wet environments and high humidity reduces the life of leather shoes.

Just Take the First Step...

Military Shoe

Military Shoe

Safety Shoe

Safety Shoe

Work Wear

Work Wear

Office Shoe

Office Shoe

Hiking Shoe

Hiking Shoe