Close

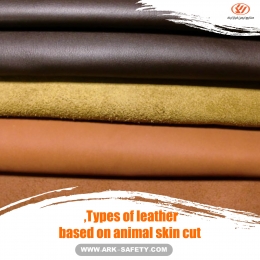

Types of leather, based on animal skin cut

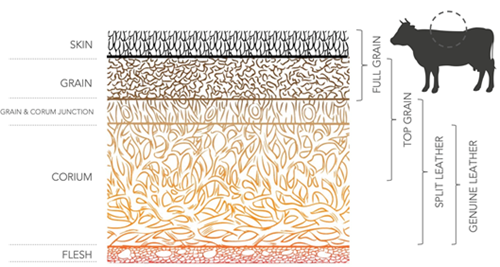

Leather is a durable and flexible material that is produced with the skin of animals. The most common raw material for leather production is cowhide. It is the leather tanning process that stabilizes and resists skin proteins, especially collagen, to increase the thermal, chemical, and microbiological stability of cow skin, making it useful to various leather products.

Cow skin is made of two integrated layers of corium and grain texture. The collagen fibers in the skin`s corium are thinner and more flexible. As you move to the outer skin tissue, it becomes thicker and firmer where the fibers are more densely and tightly wrapped. The corium layer becomes thicker as the animal ages as well. For this reason, the skin of calves is thinner and softer than the skin of larger animals. The outer tissue covered by the hair can be dotted and scratched such as insect bites, scars, or signs of burns. Sometimes it causes the upper part of the outer tissue of the skin to be peeled off and become smoother to make the leather look uniform.

Another factor influencing the quality of the leather is the physiology of the animal`s skin (cow), which is one of the most complex issues in the field of leather. Several factors are involved in the physiology of the skin and leather produced; Nutrition, climate, habitat, and skin of different parts of the animal body affect the quality of the finished leather. The skin of the face and legs of the animals has the lowest quality and the central parts of the animal`s body (back and waist) have the best quality of leather.

Types of leather, based on different cuts of the cowhide

- Grain leather

- Split leather

- Suede leather

- Nubuck leather

When the skin is completely shaved with all the top texture of cow skin, it is called grain leather. Even despite skin blemishes, grain leather is more expensive and more in demand due to its high durability. The cowhide has three general categories: aniline (ink), semi-aniline, and protected leather. Aniline leathers are processed using soluble dyes to preserve the natural texture of the skin and have no pigment or surface coating. This makes them look like natural leather, but they are more sensitive to scratches and stains. Aniline leathers are coated with pigments, thus hiding more stains. Therefore, these types of leathers have a more uniform appearance and coating, and as a result, have more protection. Protected leathers have a non-leathery coating that adheres to the cow`s natural leather as protection.

The lower part of the leather, the part where the two layers of Corium and Grain meet, is introduced by different names and can be confusing. Many people refer to this layer as "genuine leather", however, the term is not used consistently. You may come across many similar terms for this layer of skin and the leather produced from it. Modified leather, embossed leather, coated leather, dyed leather, etc. are among these titles, which here we introduce as split leather.

The middle layer of the skin can be divided into even thinner split leathers and used for various applications. A polymer coating is usually used to make split leather look like grain leather, but split leather is not as strong and durable. Another application of split leather is suede leather production, in which a special polish is applied to the leather to make it uneven and velvety. Suede is sometimes confused with nubuck leather. Suede is made of the inner part of the animal skin and has soft and short villi, while nubuck is made of the outermost layer of the skin and has high strength and is more resistant to scratches. Although nubuck is more durable than suede, due to the special softness and stability of suede, it has its application.

How to detect synthetic leather

There are several ways to simulate and produce leather. Split leather is sometimes polished in such a way that it plays a prominent role and looks more like high-value grain leather. It is not easy to distinguish artificial leather from natural leather. Today, with the development of the polymer and textile industry, various samples of synthetic leathers have been produced that are very similar in appearance to natural leather. It needs to be tested to distinguish it, but synthetic leathers, which are currently mainly available in the bag and shoe industry, can be detected by simple methods. The first method is to pay attention to the color and model of the leather`s back. The back of synthetic leather is usually made of fabric or plastic, which can be distinguished from natural leather. This type of diagnosis is also made easier by cutting the leather. Synthetic leather is usually not stretchy, while grain leather has a very slight discoloration when bent or stretched. Another method is to heat the tested leather. Natural leather, when burned with a small flame such as a match or lighter, emits an odor similar to hair burning, while synthetic leather smells like burning plastic.

Another point that should be considered by consumers is that many of the terms used in the leather industry are fixed and inconsistent in different forums. The most common mistake made in this case is to use the term genuine leather. Genuine leather is mostly used to describe low-quality split leather, while many buyers assume that the term genuine leather is used in the opposite sense to counterfeit leather or fake leather. Many sellers use the term genuine leather to express the fact that their products are not counterfeit leather. This makes customers skeptical, even if the product is made of very durable and suitable leather. Therefore, the task of Ark Safety Industry as a manufacturer of safety shoes, military boots, office shoes, and hiking boots is to have a complete explanation for its customers in the field of leather used in their products.

Just Take the First Step...

Military Shoe

Military Shoe

Safety Shoe

Safety Shoe

Work Wear

Work Wear

Office Shoe

Office Shoe

Hiking Shoe

Hiking Shoe