washing work clothes

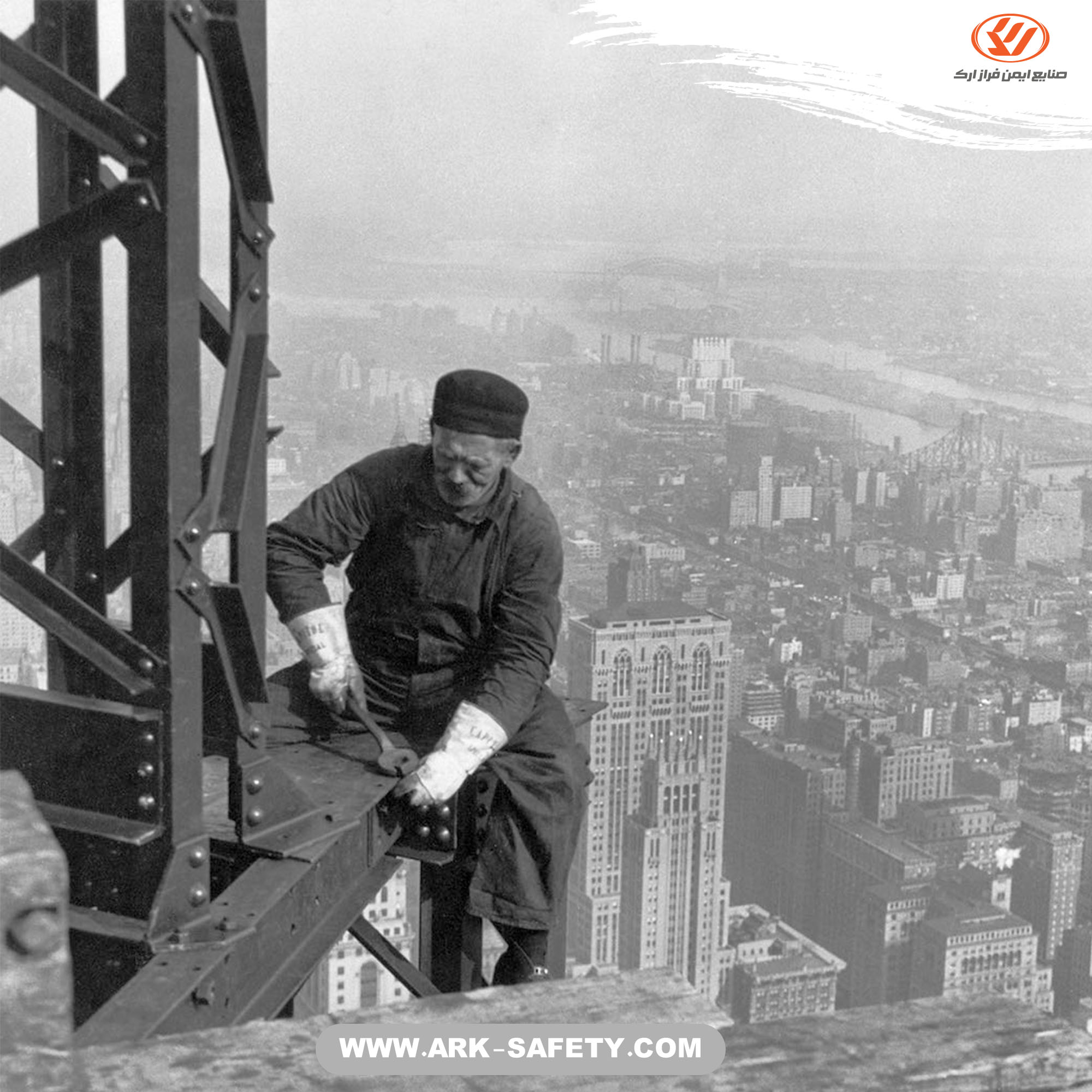

Each work condition requires unique work clothes to maintain the physical health of workers and organizational order. Saving employees` lives from possible dangers and injuries in the workplace is one of the advantages of using work clothes. For instance, as a result of exposure to chemicals and toxic materials, the workers have to wear suitable clothes like appropriate gloves, clothes, and shoes resist to these materials. Also, recommendation on the label`s chemical material is a suitable way to choose the right clothing.

Select appropriate work clothes

The selection of suitable personal protective equipment, especially work clothes is one of the concerns of occupational health experts. Analysis Safety Job method (JSA) is a good way to determine the appropriate work clothes. Evaluation of the workplace results in selecting appropriate clothes for each task. Thus, work efficiency increases.

the best approach to washing work clothes

the most important thing in personal hygiene is Washing work clothes. various detergents are used for washing. In addition, the temperature of the water has significant effects on washing clothes` work. the most important thing in personal hygiene is Washing work clothes. various detergents are used for washing. In addition, the temperature of the water has significant effects on washing clothes` work. Contrary to public opinion cold water has a more effective effect than hot water. most current detergents can work at any temperature. in spite of this fact, using cold water is better and the stains can be removed well.

essentials tip to wash clothes contaminated with chemical

• Contaminated clothes Storage must be isolated. Separating clothes work from clothes home.

• Work clothes must be washed separately from the clothes of other family members.

• A small number of clothes must be washed together.

• Regulating washing machine water at the highest level to wash contaminated clothes.

• Rinsing the washing machine after washing clothes with hot water and washing powder.

• The type of fabric clothes is important in washing.

• Putting clothes in front of the sunlight to dry is a good way to eliminate any contamination.

• Pay attention to the signs and instructions for washing clothes.

• Washing clothes by color or type of fabric.

• Zip the clothes before washing.

• At the beginning determine the amount and the type of the detergent.

• Removing the stain before using the washing machine

• A liquid detergent is a good option to wash dark clothes than powder detergents. As a result of using powder detergent, detergent grains remain on the clothes.

shop (ark ppe) : +989144745241 whatsapp

products

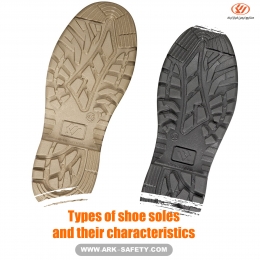

Military Shoe

Military Shoe

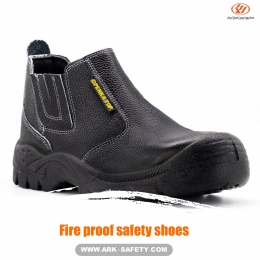

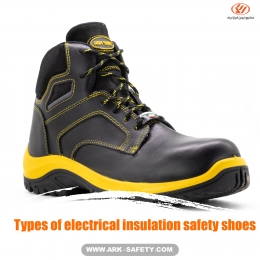

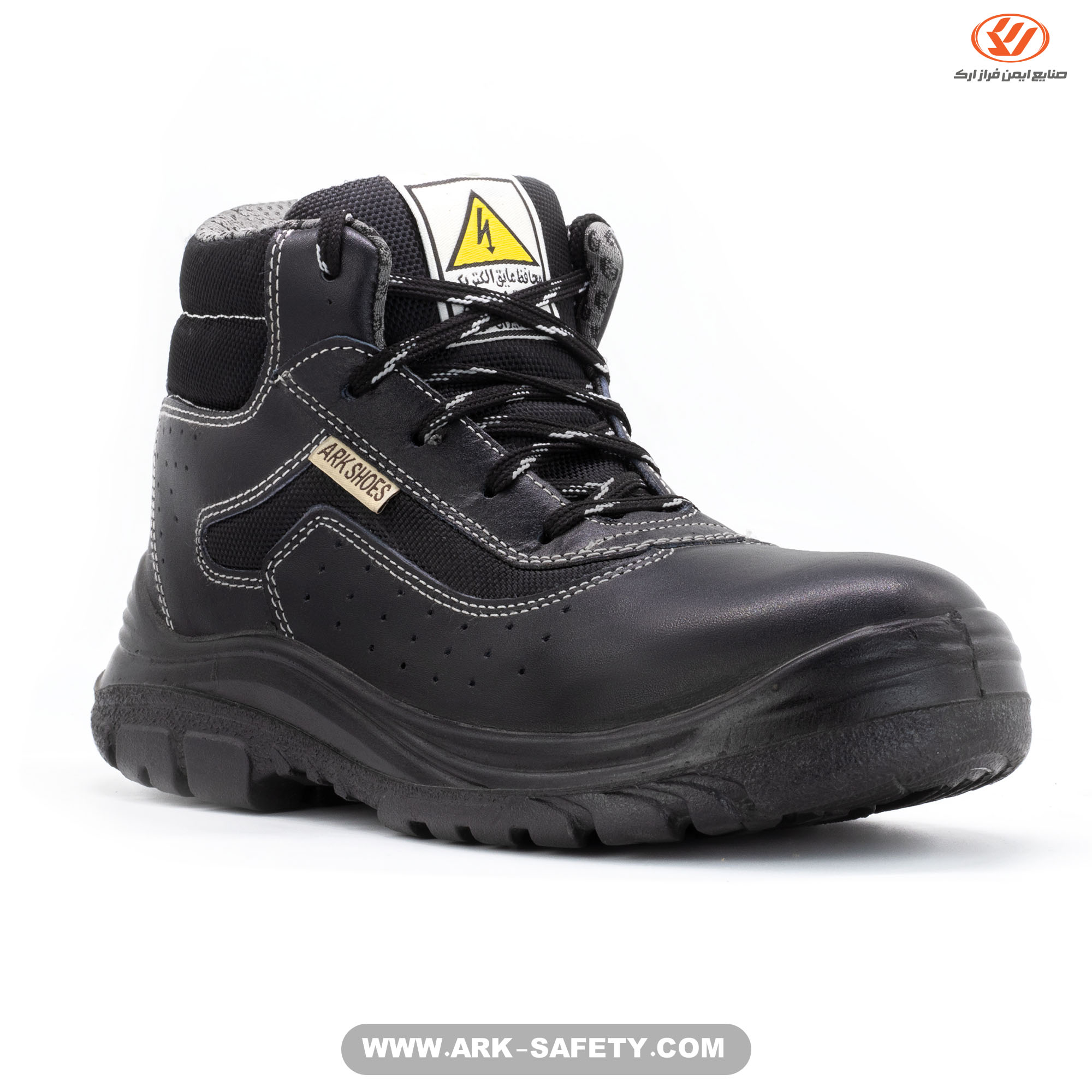

Safety Shoe

Safety Shoe

Work Wear

Work Wear

Office Shoe

Office Shoe

Hiking Shoe

Hiking Shoe