Why is it important to Wear Insoles!

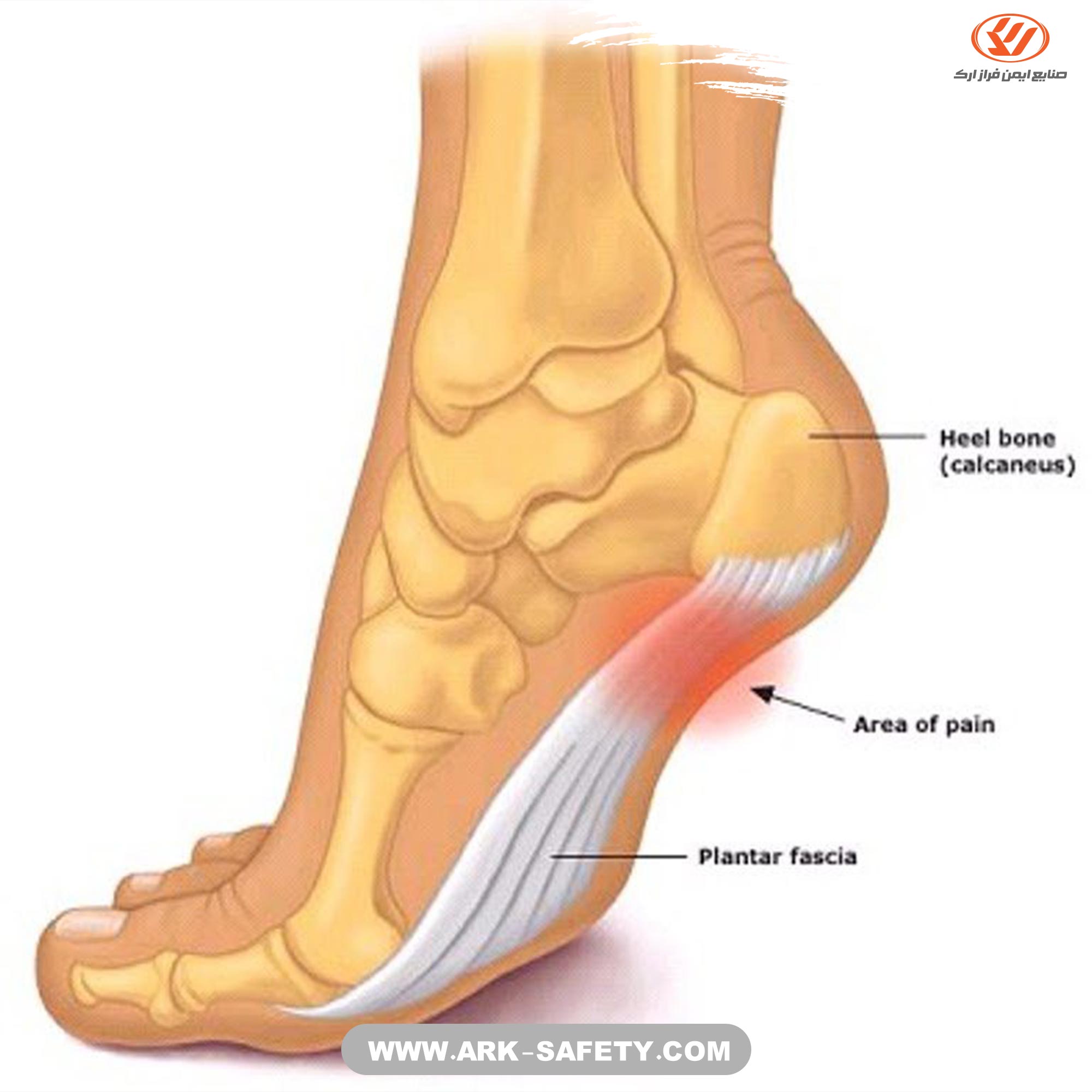

And for all workers we recommend insoles. Insoles provide arch support that is important in helping reduce strain, pain and potential long-term musculoskeletal disorders (MSDs). And, they are also another great shock absorber. Unlike anti-fatigue flooring matting, insoles provide individual foot support and travel with the worker wherever they go.

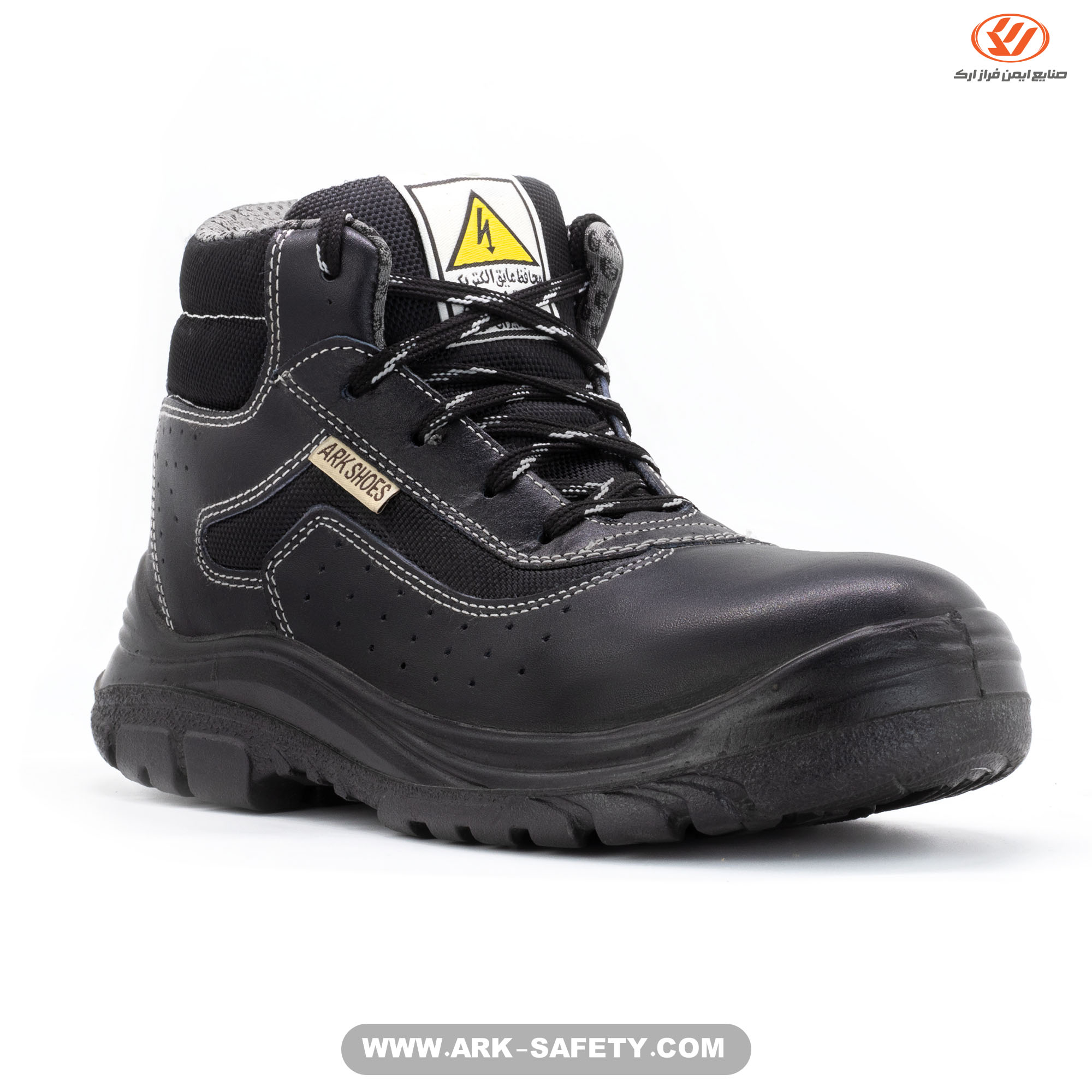

Shoes for construction operations are different depending on the conditions of the work environment. Construction work can consist of welding, thermal insulation, electrical work, cement and plaster work and even building installations and etc. Naturally, the shoes used in these environments will not be the same, for example, electrical insulation shoes require a set of standards and requirements that will be different from welding shoes, or in cases where anti-slip and frustration shoes are needed, we recommend TPU outsole. When buying, it is recommended that you share your work environment tips and requirements with our experts. They will try to offer you the best and most suitable shoes.

Please read our artcile about Workplace safety tips for more safety at work.

JUST TAKE THE FIRST STEP.....

Sources:

Mister safety

Ark Safety Group

These include:

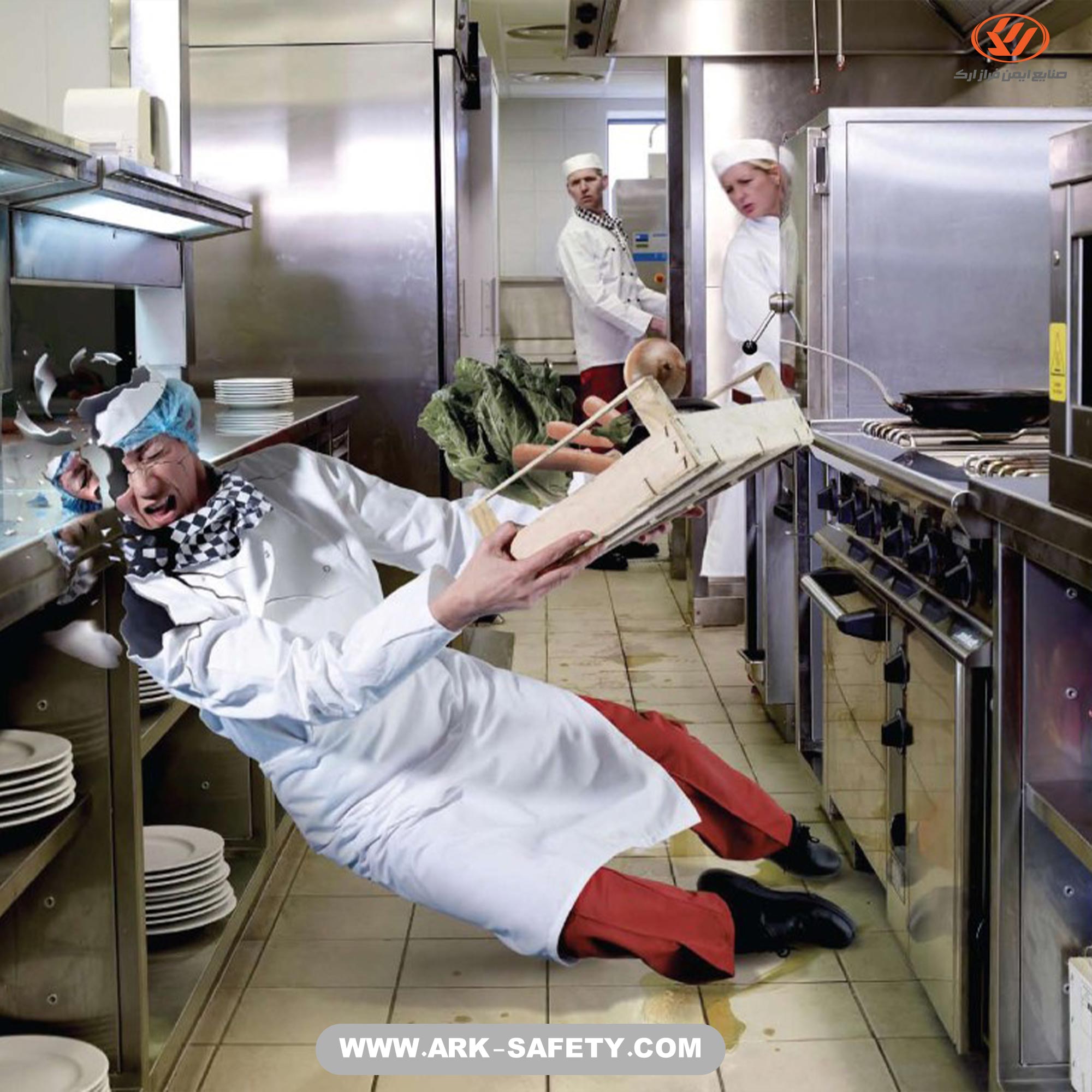

Rupture of the floor covering

Loose shelves

Stairs are not strong

Any defective device

Broken chairs or tables

Broken or loose tiles

Unprotected power cords at commuting

You must have heard the famous phrase "prevention is better than cure". Today is the age of technology and the development of industry, and it has affected human activities in all its dimensions. Each activity has its own dangers, so wisdom dictates that man protect himself from the dangers and injuries caused by accidents. Therefore, human beings have become able to protect themselves to a great extent from dangers and injuries by producing safety tools and equipment.

Therefore, creating a safe work environment is one of the main tasks of managers and employers in any part of organizations. In most cases, people are not allowed to work without safety equipment. It is important for people to know what equipment they should use to protect themselves in the workplace, what equipment for their job has been produced for this purpose, and with what characteristics these equipment should be provided.

The foot, as one of the most important part of human body that enables him to move, is vulnerable to environmental hazards such as hard surfaces, cold and heat. Since the feet support the human body and literally carry heavy weights daily, it is important to have the right shoes to protect the feet at all times, especially at work. Ark safety shoes, which are designed to protect the feet with good fit, in addition to foot comfort, relieve the body`s musculoskeletal system from stress and fatigue and prevent work accidents and long-term injuries.

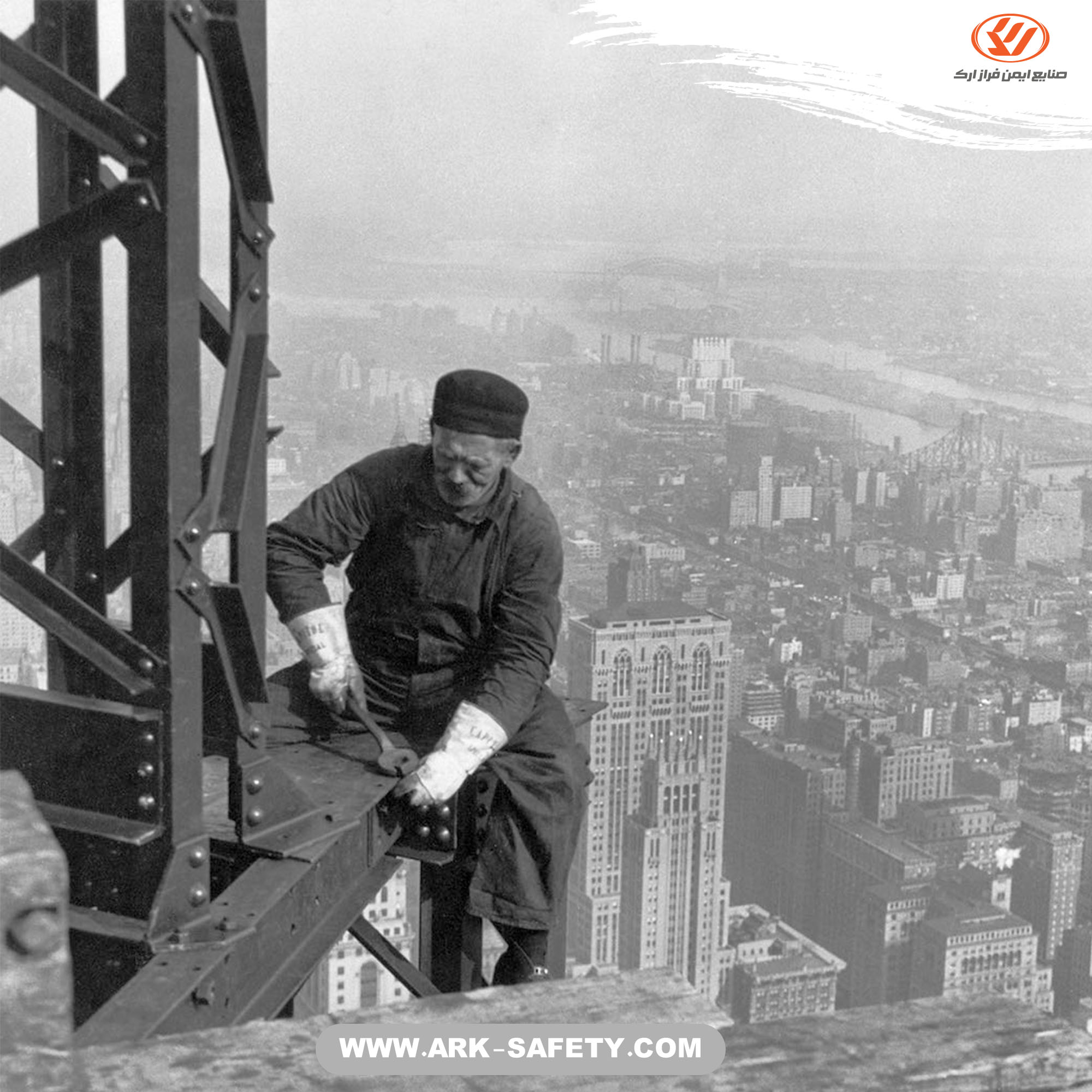

Dangerous occupations that can threaten one`s health and safety include occupations related to the foundry and metallurgy industries, petrochemical oil and gas industries, welding and forging, electrical industries, machine building, road and construction jobs, and all Workplaces where it is possible to spill molten material, jump sparks on the feet and the presence of very high temperature material. In this type of jobs, the presence of flammable and hot materials is one of the main and serious dangers that the need for thermal insulation safety equipment is very necessary. In such jobs, the use of fireproof safety shoes to protect the feet is highly recommended.

Fireproof safety shoes can withstand temperatures up to 150 ° C; And they don’t transfer heat into the shoes. Whereas the use of safety shoes is required by HSE rules and standards; For this reason, fireproof safety shoes should be used in environments such as foundry and metallurgy industries, petrochemical oil and gas industries, welding and forging, electrical industries, machine building, road and construction jobs and all work environments where there are molten materials, jumping spark on the foot and substances with very high temperatures. These safety devices also protect the feet from chemicals, petroleum solvents and oils. This footwear has two layers of outsole; And they are made of special leather that do not transfer heat inside. This shoe, like other safety shoes, has a metal layer on the front that protects the foot from heavy impact.